Background

As one of the world’s leading providers of industrial minerals and other materials, Sibelco has set an ambitious target to reduce scope 1 and 2 emissions intensity (tonnes CO

2 / revenue) by 5% per year from 2021 to 2030 – cumulatively a reduction of 37%, assuming the same scope of activities.

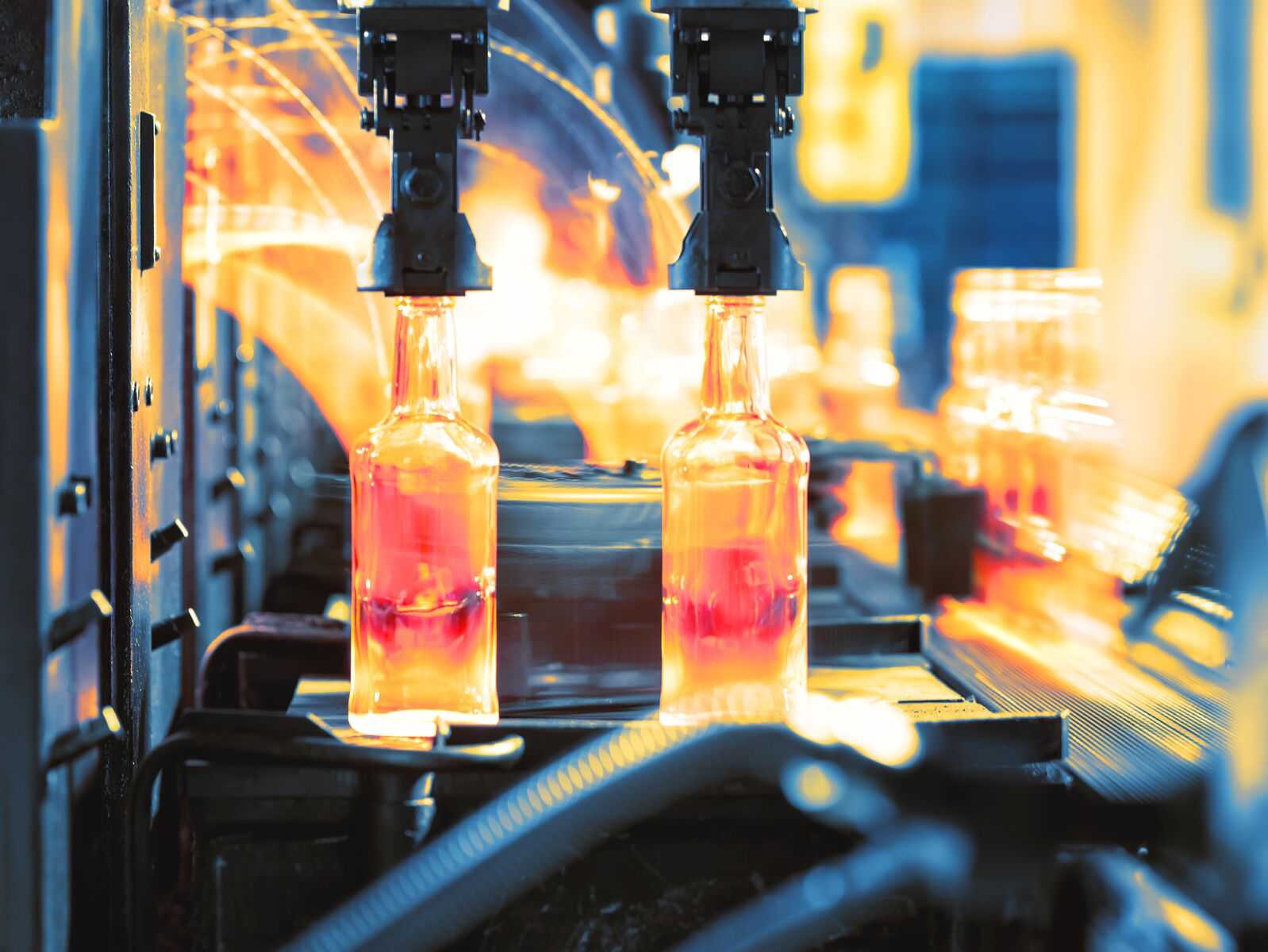

But it is Sibelco’s scope 3 emissions that account for by far the biggest percentage of the company’s carbon footprint. That is why Sibelco is working to help its customers reduce emissions in line with best practices promoted by the Science Based Targets initiative (SBTi). And as Sibelco’s second largest market, glass is a key area of research and development.

Sibelco is exploring four categories of material to reduce the overall carbon footprint of the glass manufacturing process:

- materials with a lower inherent carbon footprint

- materials to reduce CO2 emissions

- materials for low-CO2 technologies

- materials to reduce energy demand

With regard to the first category, the use of cullet is an obvious solution – every 1,000 tonnes of cullet used during the glass manufacturing process saves approximately 314 tonnes of CO

2. Sibelco is already Europe’s largest glass recycler, each year transforming over 3 million tonnes of waste glass into high-quality cullet.

1There are clear synergies between the remaining three categories - for energy-intensive combustion processes, materials that can even slightly reduce energy demand can have a significant long-term impact on CO

2 emissions.

Batch materials substitution

Redesigning the batch mixture by substituting one mineral for another can improve the energy efficiency of the glass-melting process. In fibreglass production for example, anorthosite can replace kaolin and some burned lime. Due to its chemical make-up (specifically the absence of crystalline water) less energy is required to melt anorthosite. Furthermore, the partial substitution of burned lime decreases the indirect energy costs and CO

2 emissions associated with its production.

Such batch substitutions to address emissions targets reflect the philosophy of Prokhorenko: “Improvement of conventional glass melting processes without major changes in existing technology”

2.

Tailored batch materials for melt homogenisation

Lowering the energy input from the combustion space or increasing the furnace pull leads to a risk of deteriorating glass quality. Traditionally this risk has been mitigated by the introduction of electric boosting (efficient energy input) and bubblers (forced convection). A universal approach to mitigate the same risk without requiring furnace modification is the optimisation of the glass batch to improve the quality of the primary glass melt.

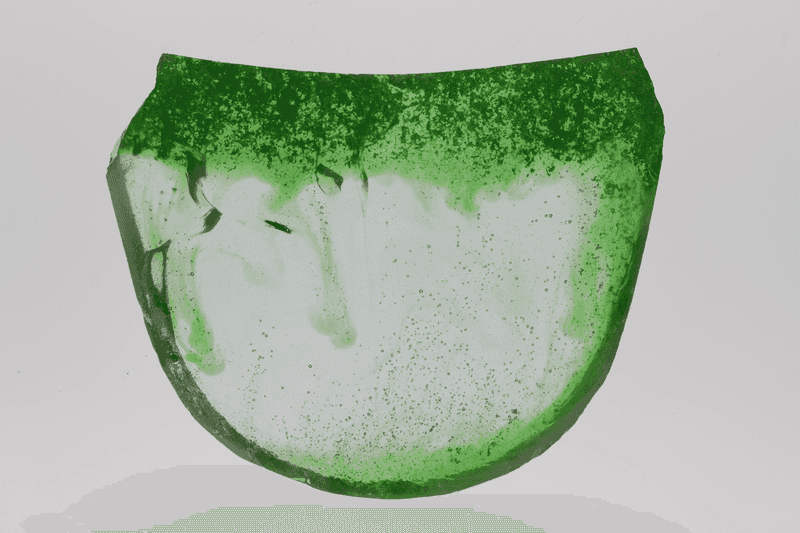

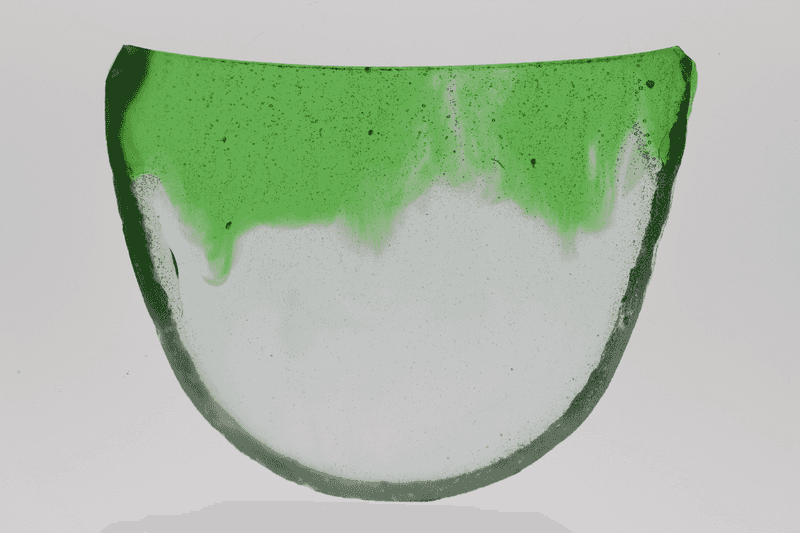

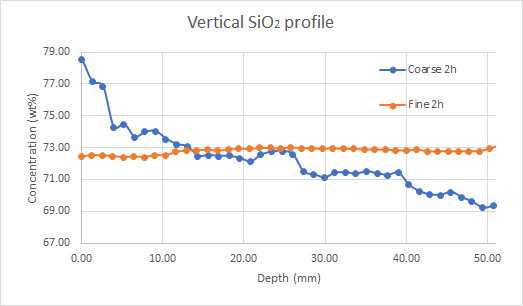

3An in-depth evaluation of glass via Scanning Electron Microscope (SEM-EDX) reveals the extent of batch segregation. A top-down composition measurement along the central axis of a glass sample (graph 1) illustrates a steep concentration gradient for silica in the case of a standard float glass batch, and the absence of segregation and silica-enrichment in the case of modified batch materials. These comparative samples were produced by melting 500g batches at 1350°C for 2 hours.

Improving conventional glass melting processes

Material solutions investigated by Sibelco offer the potential to reduce the carbon footprint of the glass-melting process, cutting energy consumption and CO

2 emissions.

The envisaged modifications and substitutions create suitable conditions within the glass furnace to increase yield (by decreasing defects), increase pull rate, and lower melting temperatures.

A further focus on primary melt quality may enable a decrease in the required residence time of the glass in the furnace; this could see further reductions in overall energy consumption and CO

2 emissions by reducing time needed to homogenise the glass.

Author:

Lesley Beyers,

Glass Scientist, Sibelco Technology & Innovation, Dessel (Belgium)

This article is published in Glass International Issue December / January 2023

References:

1

S. Hourquebie and H. van Limpt, "Sibelco Glass Recycling," GMIC/GlassTrend Virtual Recycling Seminar, 16th June 2022.

2

O. A. Prokhorenko, “Energy-Saving Glassmelting,” American Ceramic Society Bulletin, vol. 85, no. 10, pp. 29-34, 2006.

3

S. Hourquebie and H. van Limpt, "Short-Term Solutions to Keep the Melting Costs Under Control" GlassTrend Seminar on Glass Recycling & Mineral Solutions, 29th November 2022.