Sibelco high-purity magnesium olivine is a highly versatile mineral, delivering benefits across a wide range of applications including:

- Ballasting: OLIDENSE is a natural, high-density aggregate for specialist ballast and concrete applications offshore (concrete pipeline coating, wind turbine ballasting, anchoring and oilrig ballasting) and on dry land (bridges, tunnels, radiation-proofing, counterweighting and ballasting).

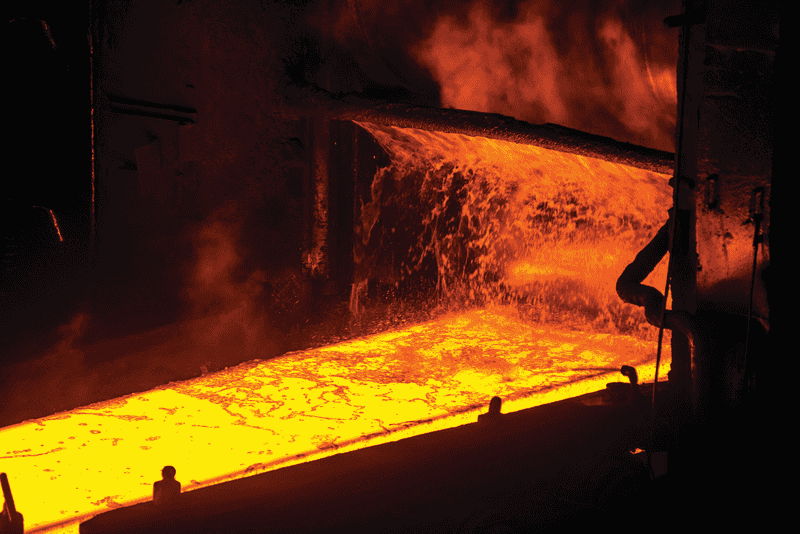

- Blast Furnace: OLIFLUX MgO as an additive for sinter, pellets and as a blast furnace direct charge material in iron production.

- Carbon Dioxide Sequestering: olivine is one of the fastest-weathering minerals, making it efficient for weathering and capturing CO2 in a variety of developing applications (enhanced silicate weather – agriculture and coastal and mineral carbonation), research is being undertaken.

- Foundry: olivine is used in foundries as sand for cores and mould construction in both ferrous and non-ferrous metal casting. It has high heat absorption, low thermal expansion and high refractoriness. Non-wetting properties make olivine perfect for manganese steel casting.

- Thermal Heat Storage: high density combined with high heat capacity make olivine perfect for storing heat energy.

- Refractory: olivine combines high refractoriness, low thermal conductivity, linear thermal expansion and low reactivity to metals and basic slags, and is excellent as a raw material in refractories for steel and non-ferrous applications. Additionally, olivine from Sibelco has an extremely low carbon footprint.

- Mineral wool: olivine delivers an stable MgO which is an integral component of mineral wool, especially in high temperature mineral wools for thermal insulation, sound insulation and fire-resistant applications.

Whilst abundant in the earth’s mantle, high-quality industrial-grade olivine deposits can be difficult to find. Sibelco high magnesium olivine is mined and processed at Åheim, the world’s largest commercial olivine operation on the west coast of Norway. The proximity of our mine, processing facility and shipping terminal enables us to run a highly efficient operation with minimal use of fossil energy or double-handling of materials. Quarried olivine is moved via a conveyor belt through a 4km tunnel to the processing plant for production of undried and dried products.

High production capacity enables us to adjust manufacturing levels to meet customers changing requirements. The deep-water terminal sitting next to the processing plant can handle conventional vessels and self-discharging bulk carriers up to Panamax size. Our shipping and chartering department can organise deliveries anywhere in the world at competitive rates.